USU Postgraduate Dental College Researcher Awarded Patent for Self-Healing Dental Composite

By Vivian Mason

Why can’t things heal themselves the way the human body does?

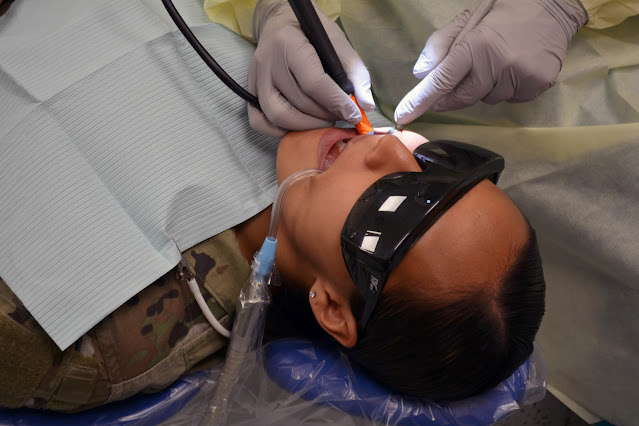

“Self-healing” has become one of the most desired and underexplored properties in materials development, and mimics the properties of biological systems like our own. For example, think about how your body heals: you cut yourself, blood oozes out, it coagulates, and then it heals that area. That same concept can, essentially, apply to inanimate – whether dental, medical, or everyday – materials. Recently, a faculty researcher from the Uniformed Services University’s (USU) Postgraduate Dental College (PDC) and the Dental Research and Consultative Services at Joint Base San-Antonio-Lackland, was awarded a patent for inventing a self-healing dental composite based on that very idea.

For the past two and a half years, Col. Wen Lien, an associate professor of the PDC and director of Dental Biomaterials Research at the DRCS, and Dr. Amber Mallory, director of Trauma and Clinical Care Research, 59th Medical Wing Science and Technology Office (STO) at JBSA-Lackland, working with scientists from STO and the Naval Medical Research Unit-San Antonio, developed a dental composite with the ability to self-heal. Now, it seems as though their efforts have finally paid off.

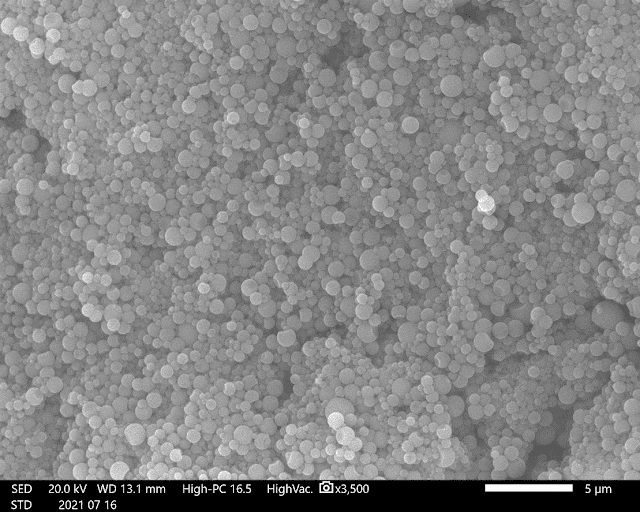

A self-healing dental composite (SHDC) works similarly to the human body. As a composite material, a SHDC is not only made from contemporary dental filling components, but it also contains healing agents that are encapsulated in nano- and microsized capsules. When a SHDC is “injured,” a growing crack ruptures capsules in its path from which “healing cargo” is released to “coagulate” the damaged site. Self-healing materials are generally designed to halt, impede, and repair fractures from increasing, thus leading to greater durability.

“The idea behind the SHDC project actually started from a hallway conversation with Dr. Amber Mallory a few years ago,” Lien says. “Initially, I examined much of the scientific literature. There was definitely a lot of research still to be performed because self-healing materials are relatively new and underexplored in the dental community. Picturing the iconic image of a chemist in a lab experimenting and concocting various chemicals isn’t that far-fetched from what we actually did in this project. Surprisingly, the secret to making the self-healing composite possible was its similarity to emulsion-making.”

“Col. Lien and I felt that this idea, and such an advancement in materials science, would be relevant across many specialties and operational situations and would also benefit the joint services,” Dr. Mallory adds.

Let’s say you visit the dentist because you need a filling. A few days later, you bite on something hard and crack it. Normally, you would return to the dentist to get the filling redone. But with the strategy of SHDC, once the material is cracked―it will still be able to repair itself, alleviating the need to return. As these microcracks develop, they break the microcapsules in their path, thereby releasing a healing agent. This agent then reacts and forms a new cement-like material that fills and seals the cracks.

“Dr. Mallory and I are always on the lookout for new materials that possess the requisite properties of an ideal dental filling,” Lien says. “And we think about and question the real role of dental filling.

“Aside from its primary purpose (to patch up a cavity),” Lien continues, “could this material be used for more than just patching a space or hole? Could it act like a wound dressing, which has the potential to repair and heal? So, we began considering the concept of a material that can autonomously heal as our bodies normally do.”

|

| Self-healing nano-capsules that were created in Col Lien's laboratory. (Photo credit: Courtesy of Dr. Amber Mallory) |

This innovation could also be tailored for other uses. Lien describes that the application of this ‘smart’ material can be expanded from dental fillings to protective coatings or even lightweight armors. For example, what would occur with body armor is the following: “microspheres” or capsules containing healing agents are embedded in armor materials. Therefore, when a bullet impacts the armor, it ruptures the microcapsules along its path. Then, the healing cargo discharges and results in coagulation, thus repairing the puncture site. “It’s quite amazing,” notes Lien.

Tremendous strides have been made in the lab to extend the service life of dental fillings made of SHDCs. Dental resins also play a significant role in a variety of dental applications, including restorative materials, cements for single/multiple tooth prostheses and orthodontic devices, inlays, onlays, cores and buildups, root canal posts, etc. SHDCs in the lab have demonstrated excellent self-healing efficacy after many optimization experiments.

“I’ve always enjoyed science and research,” says Lien, who has been practicing dentistry for more than 20 years. “They’re not only my career, but also my hobby. I’m constantly thinking about new ways to improve dentistry.” In addition, Lien says he also enjoys mentoring residents. “Often when talking with the residents, they give me even more ideas and problems to think about.”

And, Lien confesses, “I love the creativity and challenge involved in solving them.”